Material scientists are constantly trying to find new materials with specific properties but the experimental data they have to wade through is overwhelming. Scientists at the University of Rochester used machine learning to fast-track new materials discovery.

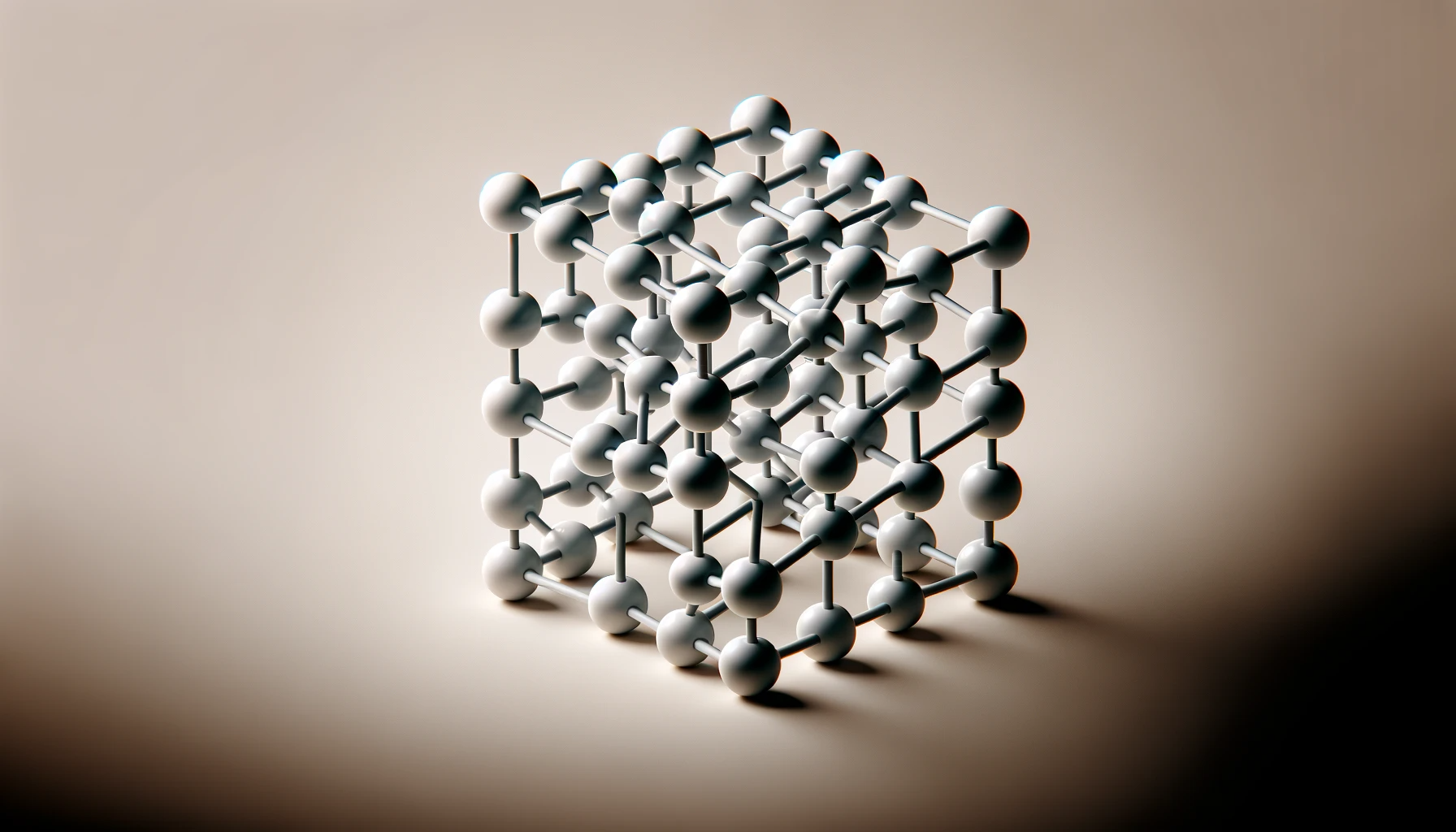

Crystalline materials have a well-ordered, repeating crystal lattice structure, a regular, repeating arrangement of atoms, ions, or molecules. The arrangement of these crystal lattices is what gives a material specific properties.

Want a material that’s hard, handles high temperatures, and is lightweight? You’ve got to get just the right lattice structure to make that happen.

When material scientists synthesize a small amount of a new material they want to know what kinds of properties it will have to decide whether or not it is viable for a particular application.

They use a process called X-ray diffraction (XRD) to do this. The material sample is normally ground into a fine powder and then exposed to X-rays. As X-rays hit the atoms in the material, they are diffracted in various directions, depending on the atomic arrangement.

The diffracted X-rays create a pattern on a detector that the scientists need to analyze to infer the properties the material has. The problem is that XRD produces a huge amount of data that is beyond the ability of humans to process effectively.

Automating material analysis

The study, led by materials science PhD student Jerardo Salgado, developed deep learning models to automate the classification of materials based on their XRD patterns.

The machine learning models they used employ convolutional neural networks (CNNs), a type of neural network that’s really good at performing image recognition and classification tasks.

The models were trained on a large dataset of synthetic XRD patterns, which were generated to represent a wide range of experimental conditions and material types.

Project lead Niaz Abdolrahim, a mechanical engineering professor at the University of Rochester said, “There is a lot of materials science and physics hidden in each one of these images, and terabytes of data are being produced every day at facilities and labs worldwide.”

Explaining the benefits of machine learning in his field, Abdolrahim said, “Developing a good model to analyze this data can really help expedite materials innovation, understand materials at extreme conditions, and develop materials for different technological applications.”

Using machine learning models to filter XRD data could speed up the development of faster electronics, better batteries, or even everyday items with enhanced durability, functionality, or sustainability.

Researchers from the Center for Matter at Atomic Pressures have a particular interest in this application of machine learning. Using XRD while exposing materials to extreme pressures and temperatures will help scientists not only discover ways to create new materials but also learn about the formation of stars and planets.

Using AI to free scientific minds from the drudgery of data analysis will see their creative thinking better directed at designing the materials that will shape our future.